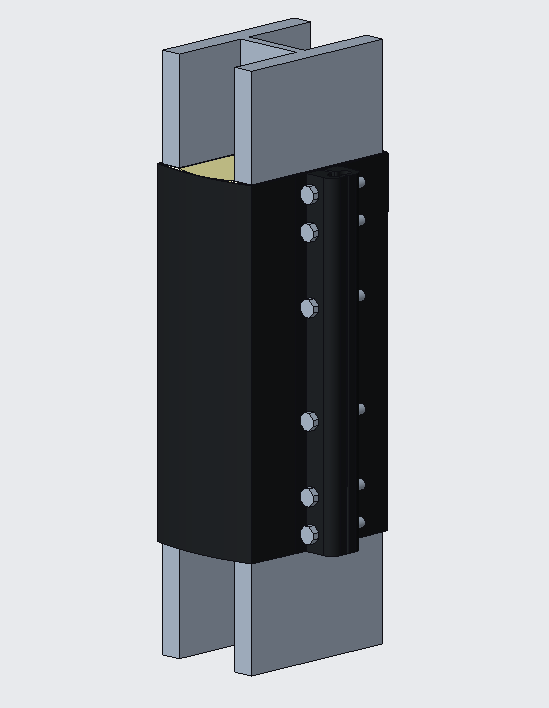

RETROWRAP H is a wraparound corrosion protection solution for inshore splash zone and underwater corrosion protection for H-piles. RETROWRAP H is specifically designed as a long-term solution to endure rough conditions at hard storms and big temperature variations.

RETROWRAP H is designed to suit H-pile sizes up to about 1 X 1 m square dimensions and it can be interlocked to accommodate any required protected length.

First class corrosion protection is achieved by wrapping the protected area with corrosion protection inhibitor gel impregnated into a felt layer. The felt is pressed and hold in place by tailor made urethane fill-up pieces (in the H-pile middle part) and finally the tensioned outer coated fabric panel. Ends of the Retrowrap assembly are sealed to ensure a solid solution. RETROWRAP H panels are a multi-layer monocoque construction, like in Retrowrap HD2, consisting of a polymeric textile reinforcement encapsulated within the polyurethane matrix and outer layer.

- Maintenance free corrosion protection concept

- Cost effective installation. Quick, easy and safe to install

- Environmentally friendly and low lifespan Carbon Footprint due to long design lifetime, 25 years.

- Minimal operational lifetime costs

- Easy removal and replacement for inspection

- Minimal pile surface preparation -does not require substrate shot blast preparation

- Cold-applied – no hot work permit required

- Hoop tension forces created within the outer skin resist high wave suction forces and sea growth

- Material to retain hoop tension throughout the projected operational life of the fabric

- Multilayer fabric, heavy-duty construction

- Supplied in interlocking modular lengths

- Polyurethane provides the highest abrasion resistance

- Provides active protection with environmentally safe corrosion inhibitors

- Excellent UV, Ozone and Oxidization resistance

- Resistance to high climactic temperature variations and hydrocarbon oil contamination

- May be fitted with corrosion rate monitoring